A place for everything, and everything in its place. It’s an old adage that rings true in the home, the office, and most especially, in the warehouse. But even if every SKU is neatly tucked away in a properly labeled bin, are you certain that your distribution business is operating at peak capacity? What if your warehouse isn’t organized for optimal product placement? What if your products aren’t located in the most sensible place for the fastest picking? It’s nearly impossible to manually determine what products should go where. How do you set up your bin locations so that your pickers can quickly pick orders? If pick paths are slowing down your order fulfillment, it’s time to consider slotting optimization.

Inefficiency in Product Location

When Atlanta Dental first implemented Latitude WMS, they weren’t utilizing the optional Slotting Module. They underwent the standard implementation process, and initially, the improved order accuracy was a boon to the business. However, Atlanta Dental found that order fulfillment times weren’t improving, even as inventory accuracy increased.

“We noticed that our pickers were walking all over the place when they were picking orders,” says John Hanna of Atlanta Dental. “They didn’t have any kind of set pattern; they were walking all the way to the back wall multiple times, making the whole process inefficient. It occurred to us that we hadn’t put enough emphasis on bin location placement.”

The Ever-changing Warehouse

Even though Atlanta Dental was utilizing Latitude WMS, significant changes to the sales of certain products had suddenly thrown a wrench into their pick paths.

“In our operations, warehouse movement and product location are dynamic. It’s almost as if our warehouse is a living, breathing thing,” says Hanna. “Optimal bin locations change on a month-to-month basis, as new products come in and old ones are retired. We have to continually re-examine and then re-organize our items to keep efficiency at its highest level.”

Manually analyzing and determining item placement would be time-consuming and arduous to say the least. That’s why Latitude WMS offers advanced features like item slotting.

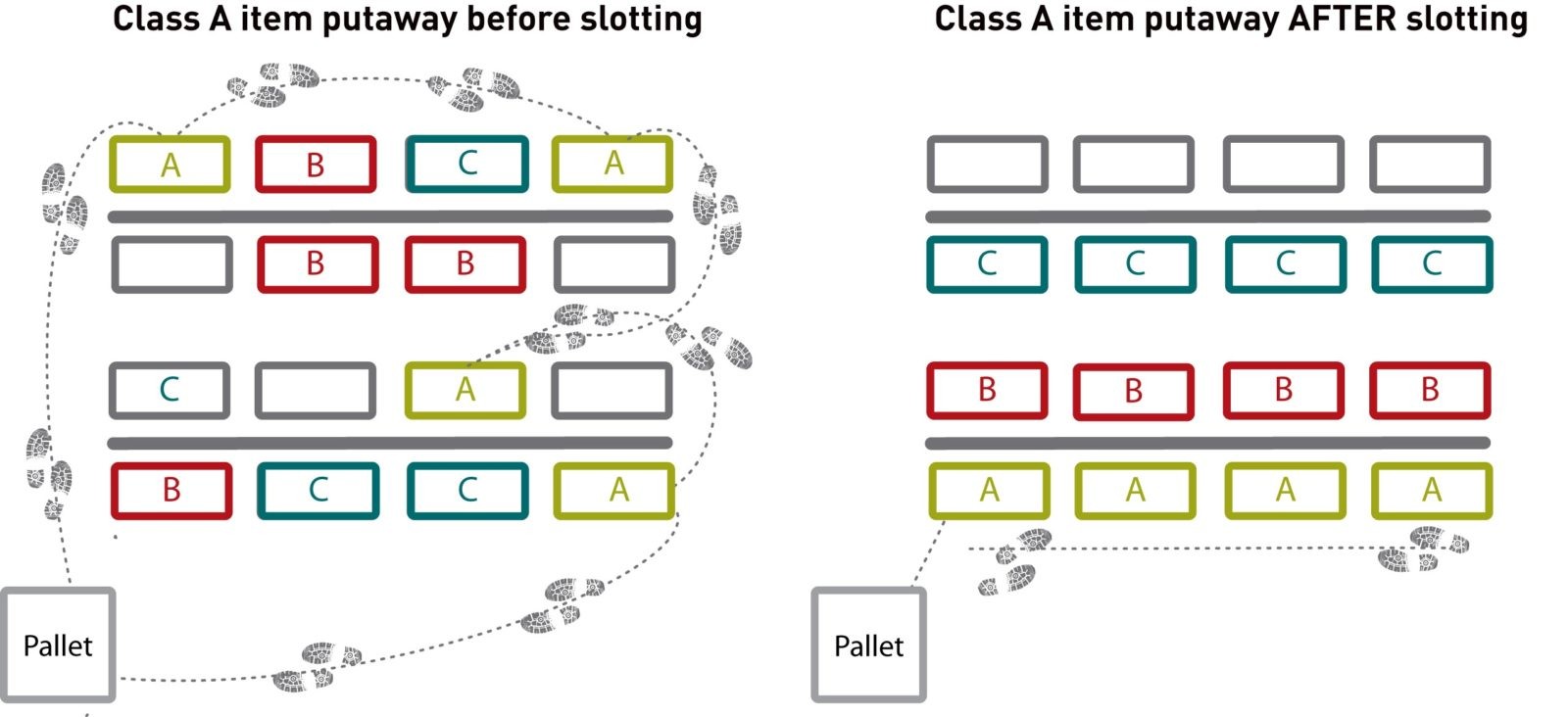

Slotting is an automated process whereby your product sales are analyzed and SKU locations are suggested, based on velocity class. You choose the products that you want assessed, and Latitude will tell you where those items need to be located to make putaway, picking, and shipping faster and easier.

Atlanta Dental began implementing the Latitude Slotting Module the very day it was released to the public. They saw an immediate improvement in picking efficiency.

“You can directly observe this by just watching the pickers,” explains Hanna. “They rarely stray off of our main pick path – and when they do, it is only just for one item every now and then.”

But what benefits can that kind of improved efficiency actually bring to the warehouse? After all, it’s just reducing the number of steps that a warehouse worker takes in a day, right?

How about cutting 80 hours from your payroll every week?

“We’ve saved at least two full-time positions, so far, with only the fastest moving items slotted,” Hanna tells us. “We used to have to bring in extra help during the afternoon shifts, but with the increased efficiency in picking, we don’t have to do that anymore. We’ve still got two-thirds of the warehouse left to slot, but that many hours already? That’s a lot of savings.”

Boost business performance through accurate fulfillment processes with Latitude WMS!