WMS or ERP: Which One Is Right?

When you invest in an ERP system for your distribution business, you may be offered a WMS module as a part of the ERP purchase. These WMS add-ons are popular for several reasons: they usually integrate with the ERP system well, they are often easy to implement, and they are (frequently) less expensive than a best-of-breed warehouse management system.

However, these ERP-based systems lack the fundamental functionality and warehouse focus that a real warehouse management system should have.

1. ERP-based WMS is slow

ERP-based WMS systems actually tie up ERP licenses, because they run on the same system; that means that warehouse work can actually slow down back office operations like accounting. A true warehouse management system like Latitude has a different set of licenses, and won’t tie up your ERP.

2. ERP-based WMS has out-of-order label printing

When ERP-based WMS systems print item labels during receiving, the printing is random and out of order. A best-of-breed WMS like Latitude prints labels as items are being received, so there’s no manual sorting required.

3. ERP-based WMS takes a long time to learn new bar codes

Bar codes need to be learned in just milliseconds, but ERP-based “solutions” can take several minutes to learn and process a single new bar code. A real WMS like Latitude learns bar codes so fast that you don’t even notice it. Just point your scanner at the new bar code, scan it, and follow the simple prompts. Within milliseconds, Latitude knows the new bar code.

4. ERP-based WMS doesn’t work in real-time

ERP-based systems don’t always post warehouse processes back to the ERP in real-time. That means that warehouse staff might be directed to an empty bin for picking (because the picking job that emptied the bin is still in progress and the ERP system doesn’t realize that the bin was just emptied). Latitude processes all warehouse transactions in real-time. So if an order is being picked, inventory is updated in Latitude in real-time, so Latitude always has an accurate picture of where inventory is.

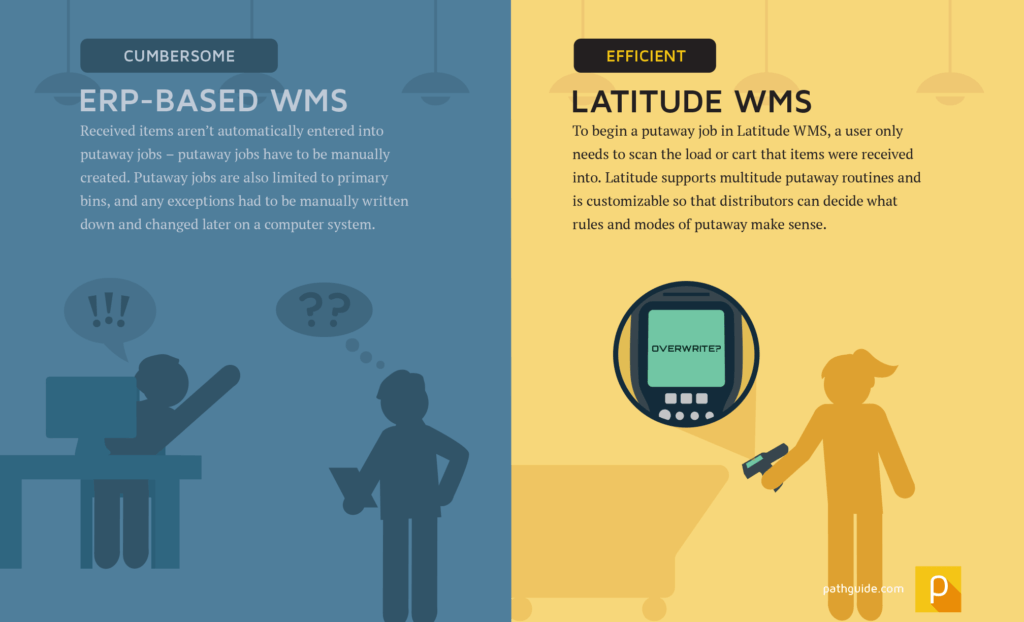

5. An ERP-based WMS is less automated than a best-of-breed one

ERP-based WMS systems require some awkward manual workarounds to launch very basic warehouse operations, like receiving. Latitude is fully automated, so starting a new putaway job is as easy as scanning a receiving tote.

6. ERP-based WMS makes shipping tricky

Finishing order picking in time for various carrier cut-off times is hard to do with an ERP-based WMS. Latitude, however, lets your sort your orders by carrier, so you always know how many more orders need to be finished before FedEx arrives for the daily pickup.

To sum things up

Our warehouse management system is a better value – not just because of competitive pricing, but because of the kind of individual attention that we provide. Most vendors, be they big or small, don’t have the bandwidth or dedication to truly understanding your business objective and needs before they sell you their product.

PathGuide maintains a highly skilled, professional support team that works closely with our software engineers to solve any customer issues that may arise. We create personalized business solutions by delivering products that are designed to meet each customer’s unique customer requirements.

Need more reasons to like Latitude WMS? Click on these links to learn more about things like customer specific labels, inventory replenishment, route shipping, hardware solutions, and tool crib management.